Accruent Releases Maintenance Connection v2021.1 Ffor the Cloud

Explore new Accruent releases and learn how to implement new capabilities within your facility.

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Self-Service & Support

Looking for self‑service training, best practices, helpful videos, product resources, or support? You’re in the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

Get a better understanding of passive and active RFID tags in hospitals so that you can make an informed decision.

Table of contents

By Kapil Asher

I was blown away by the fact that a paper thin electronic sensor could essentially make anything in the physical space identifiable in the digital world. The terms "Internet of Things" and “IoT” were not commonly used back then.

From a 10,000-foot view, the technological nuances of wireless tracking can be intimidating, but once the basics are understood, it can be an extremely powerful tool. Notice the use of the word “tool”, because that’s exactly what wireless tracking is – an enabling tool and not an entire solution. Tools such as Real-Time Location System (RTLS) and Radio-Frequency Identification (RFID) play a primary role in automation, specifically in the hospital workflow.

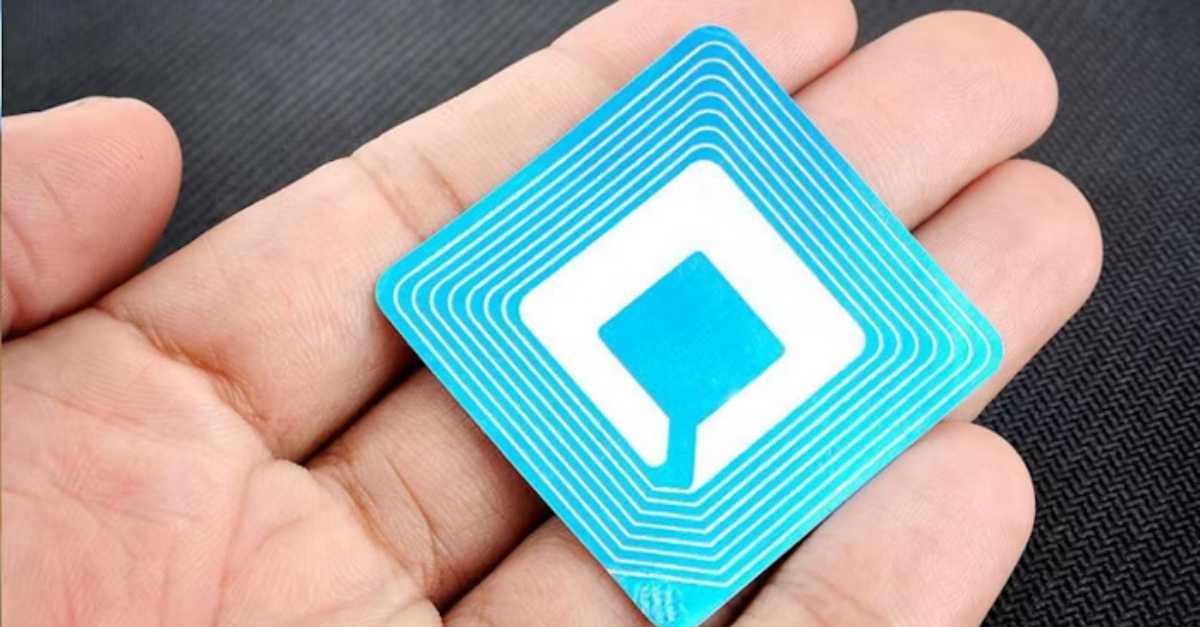

RFID is the blanket term that refers to Ultra High Frequency (UHF) Gen2 Passive radio frequency identification technology. It is usually called “Passive RFID”, because in a normal state, the tags are not powered by an external source such as a battery.

The tags are energized only when they are within the RF (radio frequency) field of a device typically called the RFID reader or interrogator. Passive RFID operates in the Industrial Scientific Medical band approved by the Federal Communications Commission (FCC). This band spans from 902 - 928MHz, typically the size of a network router powered by AC supply or over the Ethernet (PoE).

The readers are connected to antennas which disperse the RF field that energizes the tags. Since the passive tags are energized only when they pass through the RF field from these antennas, selecting the locations for installing them is one of the most important design criteria in a passive RFID deployment. Different antennas have varying shapes of RF fields (RF bubble), which are published by each manufacturer.

The limited coverage of a single antenna point warrants the need for installing the RFID readers and antennas at every location where tracking is required. The advantage of the limited coverage is that a specific antenna can be tied to a single location, and as tags are read, the system updates their last known location. The nature of coverage provided by an RFID antenna allows solution architects to design a system with varying degrees of location granularity, achieving accuracy at the facility, floor and room level.

Depending on the nature of the installation, the RFID readers can detect the presence (or absence) of tagged items (e.g., used equipment in soiled rooms) continuously, or act as a checkpoint for loss and theft prevention at critical chokepoints (e.g., laundry chutes and dock doors). RFID-enabled chokepoints can also be used to detect equipment entering or leaving large rooms such as central distribution or a biomed shop. Using these chokepoints at entrances and exits – instead of covering the whole room – lowers cost.

Another advantage of passive RFID is that the tags can be read using iOS and Android-based mobile devices with a handheld attachment, allowing users to locate tagged equipment hidden (intentionally or unintentionally) inside closed bins and cabinets, behind ceiling tiles, or under desks, sinks – you name it.

Passive RFID has grown in popularity within the hospital community because the tags typically cost $2 to $5 per unit and eliminate the need for battery management. However, location accuracy depends heavily on system design. Being battery-less, the tag response is not very sensitive to the reader signals. Solution architects must ensure that the designed system can energize tags in all locations, keeping the RF field pattern in mind. The response of the tag may also be dampened by environmental conditions, such as the presence of metal and liquid between the antenna and the tags, which makes placement of tags on the assets themselves critical. In some cases, the system can suffer from "overdesigning". For example, when the RF fields of two antenna read-points – intended to cover two different locations – overlap in the reader range, causing a cross-reading of the tagged asset.

RTLS is a term that typically refers to using active tags for tracking. RTLS is called “active” because the tags are constantly powered by an external source such as a battery or AC power. The tags provide real-time tracking visibility by constantly pinging their locations within a facility.

RTLS tags have multiple ways to identify their locations within a facility, one of which is triangulation used by the network of Wi-Fi access points. A basic RTLS system with floor- or area-level accuracy does not require the installation of additional infrastructure within the hospital, provided the Wi-Fi network is supported by the RTLS technology.

However, if room- or zone-level accuracy is required, most RTLS systems require additional sensors that must be installed in strategic locations.

Similar to passive RFID, these sensors are tied to a single location. As active tags pass through their field, the system updates their “last read location”. These sensors are typically powered by their own batteries.

As the name suggests, RTLS provides continuous location information of all tagged items within the entire facility. The technology is particularly popular for highly mobile assets such as wheelchairs and patient beds – larger assets that typically do not have a permanent station. RTLS provides facility-wide coverage which is cost-prohibitive for passive RFID, as it requires installation of readers and antennas throughout the hospital.

RTLS has gained momentum in recent years for tracking staff, including nurses, doctors and even wandering patients. RTLS tags also provide buttons that can be programmed to trigger on-demand alerts and notifications. Another common application for RTLS tags is monitoring the temperature of vaccines and other medications – alerting staff if something is out of compliance.

Hospitals can benefit tremendously from RTLS, but they must also understand the limitations of Wi-Fi-based location tracking. Access-point-based triangulation is not accurate and can compromise data integrity, especially in closed-loop equipment distribution workflows where soiled and clean rooms may be located next to each other. Without installing additional location sensors as described, it is very difficult to ensure that tagged assets are located in a given room. Erroneous alerts can be generated by the system assuming the presence of equipment in the wrong category of rooms.

As a result, solution architects must analyze the workflow and design the system using the right combination of location sensors for high-accuracy use cases. In addition, the deployed solution must factor in the usable battery life of the tags and location sensors, and alert users of potential battery failure. Unlike passive tags, active tags cannot be detected if the battery needs to be replaced, rendering the tags useless. In some cases, tag size and operational temperature of active tags is a limiting factor for their usage.

In the past decade, I have seen dramatic progress in RFID and RTLS technology. Performance improvements, new features, smaller devices and lower costs are a testament to the considerable investment that companies have made in the technology and all the hard work from some smart engineers. With the revolution of smart devices and the Internet of Things, I’m excited to see what the next 10 years will bring.

Powerful software platforms, combined with sensors, can collect more and more data from the physical space. Intelligent algorithms and process workflows can generate a level of automation and accuracy that is staggering to comprehend.

As hospitals continue to streamline workflow processes, they would do well to keep a finger on the pulse of these growing IoT technologies, because their advancement has already begun to shape the future.

Explore new Accruent releases and learn how to implement new capabilities within your facility.

Remote, multi-device tools – like an offline, native mobile CMMS – are crucial in today’s connected workplace. Here’s why.

Meridian EDMS integrated with Maintenance Connection unifies engineering and maintenance teams with streamlined access to accurate dynamic asset ...

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.