5 Trends Shaping the Future of Document Intelligence

Uncover five trends that will drive document intelligence to help you prepare for and understand how to approach the future of intelligent document management.

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

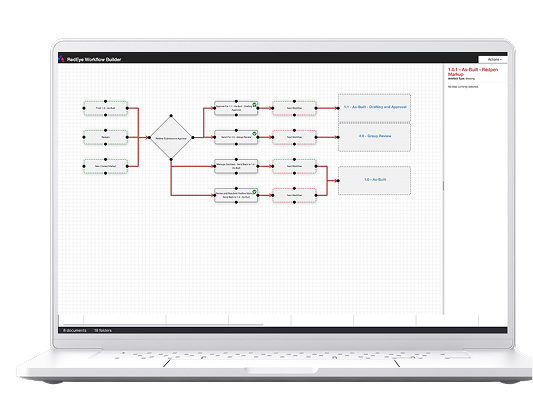

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Self-Service & Support

Looking for self‑service training, best practices, helpful videos, product resources, or support? You’re in the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

CHEMICAL MANUFACTURING SOFTWARE

Leverage predictive maintenance and real-time monitoring to prevent unplanned stoppages and extend the life of critical equipment with Accruent’s EAM suite, built for chemical manufacturers.

Increase operational efficiency and maximize ROI by streamlining maintenance, ensuring compliance and leveraging IoT for proactive issue detection.

Centralize documentation, automate task tracking and enforce secure e-signatures and version control to maintain full visibility into compliance activities.

Integrate EDMS and IoT data for real-time insight into asset health. Improve uptime and reduce repair costs through efficient work order scheduling, spare parts management and accurate demand forecasting.

Enforce version control and revision history automatically to ensure every technician, contractor or engineer is always working off the latest, approved asset records.

Place up-to-date asset data and work-order details in technicians’ hands, online or offline. Capture real-time updates, right at the point of work.

Stay ahead of failures and reduce the mean time to repair (MTTR). Plan, schedule and track preventive maintenance while automating tasks and simplifying compliance within one intuitive platform.

Search, view and annotate CAD drawings instantly from any browser or device. Provide unlimited users access, ensure compliance and maintain strict version control.

Deploy an on-premises EDMS built for compliance-heavy operations, with flexible workflows and tight access controls.

What Our Customer Says

By centralizing critical records such as asset documents, SOPs, and maintenance records with enforced version control and streamlined compliance, Accruent’s EAM suite ensures teams follow up‑to‑date procedures, reducing safety incidents and streamlining audits.

Yes. With built‑in offline sync, technicians can view and update work orders, drawings and SOPs without connectivity. Changes automatically sync once back online.

Specialized EAM solutions like Accruent’s offer advanced compliance workflows, native CAD viewing deep metadata and other dedicated capabilities that generic file sharing platforms do not provide.

Accruent’s open APIs connect seamlessly with organizational systems such as ERP, GIS and maintenance solutions, automating asset data flows and eliminating duplicate entries.

Timelines vary based on organizational needs and system complexity. Accruent's team collaborates closely with clients to ensure a smooth rollout that meets organizational requirements.

Don’t see your question? Let us help you

Experience the benefits of Chemical EAM software

Uncover five trends that will drive document intelligence to help you prepare for and understand how to approach the future of intelligent document management.

Learn how to reduce downtime and enhance labor productivity to make better decisions and gain insight across your maintenance operations.

Download our whitepaper to discover the top five factors when choosing your EDMS and the impact it can have using case studies to demonstrate real-world impact.

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.