How Preventive Maintenance Schedules Benefit Your Company

Preventive maintenance is crucial for any manufacturing organization, helping to drive down costs, improve efficiency and more. Here's how to get it ...

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Self-Service & Support

Looking for self‑service training, best practices, helpful videos, product resources, or support? You’re in the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

Ensure that your PMs are completed in a timely manner and optimize asset performance by following this basic calculation.

Table of contents

It does not matter if it is 20 percent of their day or 100 percent of their time; if you are not managing your preventive maintenance within the 10 percent rule, it’s likely that your PM program is not doing what it should for your assets.

The idea behind the 10 percent rule is that all preventive maintenance activities are completed within 10 percent of the due date in relation to the PM cadence. When performed on a regular basis, preventive maintenance can help extend the life of your assets. It can improve the overall operation of equipment, helping to reduce reactive issues and unscheduled downtime that can be a drain on your resources.

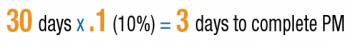

To truly gain the benefits of preventive maintenance, it is imperative that the team implements the 10 percent rule of preventive maintenance. For instance, how long do you give your team to complete monthly PMs? A week, two weeks, the entire month? To adhere to the 10 percent rule, it must be completed within three days of the start date—either 1-1/2 days before or 1-1/2 days after:

In doing so, you can guarantee that your PMs are completed in a timely manner to optimize asset performance.

Let us say you do not have the 10 percent rule in place and you give your team 30 days to complete PMs and still remain in compliance —after all, they are not the highest priority with reactive requests that come in). With that in mind, the following occurs:

Now, the issue is that between April and May, there are only five days between PMs. But, between May and June, there are nearly 50 days. Without being set on a regular schedule, a preventive maintenance program is simply ineffective.

If you leverage an automated asset management solution like 360Facility, you have the opportunity to set your service-level agreements, or SLAs, within the solution to easily track and set completion dates within the 10 percent rule. As a result, you can stay in compliance, extend the life of your assets and improve the overall operation of your equipment.

To learn more about planned preventive maintenance, contact us today!

Preventive maintenance is crucial for any manufacturing organization, helping to drive down costs, improve efficiency and more. Here's how to get it ...

The right CMMS can help your organization minimize downtime and extend asset life. Here's how.

Still trying to differentiate between CMMS, EAM, and CAFM systems? Here are the key distinctions, and how to find the best tool for your business.

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.