Going Remote: How Leveraging SaaS EDM Solutions Keeps Companies Running

Cloud-based engineering document management systems are ideally suited to enable remote work and access for greater business continuity.

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Self-Service & Support

Looking for self‑service training, best practices, helpful videos, product resources, or support? You’re in the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

Digital access to accurate engineering information will continue to be critical for plant safety, operational efficiencies, and business continuity.

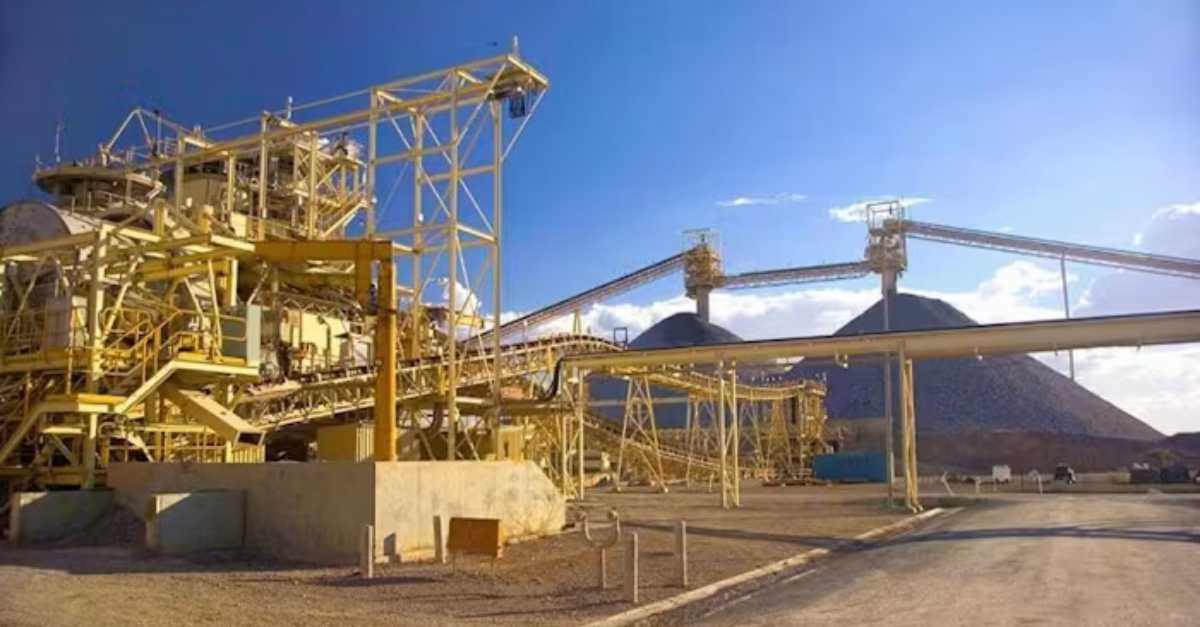

COVID-19 has brought a number of challenges to the forefront, such as how most information handoffs have traditionally been done in person. This is not only cumbersome and inefficient but is now also potentially dangerous for employee safety. This highlights how vital accurate and digitally accessible engineering information has become for manufacturing organizations.

Managers and operators must be able to adapt to new and changing conditions, whether an emergency shut down, malfunctioning equipment or a global pandemic like COVID-19. It is essential for maintaining plant uptime that employees be able to remotely access the latest engineering documentation and drawings.

Ensuring employees have access to accurate engineering documentation and drawings to make those decisions is critical. In the past, employees could interact in-person regarding system or asset checks. With large portions of the workforce going remote and each employee trying to minimize time on-site, they need to be able to rely on their digital engineering information to make decisions. Due to COVID-19 and new pandemic-related social distancing restrictions, having software in place to limit social interaction is critical to keeping business moving.

But what if accurate digital engineering data is not available? Employees may then spend critical time searching for that information and increase the risk of human error.

The start of 2020 has created unique and unusual situations for manufacturing facilities and organizations by needing employees to go remote. Typically, an employee will have to physically check equipment or search for physical engineering documentation. If the engineering drawing and documents are digitized and accessible remotely, employees always have access to the necessary documentation so they can make time-sensitive decisions without delay. This makes it possible to act appropriately for any given scenario.

Outdated engineering documentation and drawings can now easily result in extended exposure on-site. Operators and engineers must ensure that employees minimize their time on-site while ensuring the upkeep of their facilities. Organizations must also be able to resist the need to perform maintenance that can end up causing extended interruptions, which can be compounded even further if there is a lack of accurate digital engineering information.

To avoid these additional interruptions, digital information must always be up to date. Engineering document management (EDM) and building information modeling (BIM) are supported by various tools and technologies that generate and manage digital representations of physical and functional drawings of assets and buildings.

Solutions like Accruent's Meridian can manage drawing versions and maintain an audit trail, so every version of each drawing is retained. This creates a single source of truth for both engineering and maintenance management. Following the processes built into the system can also eliminate the possibility of inadequate digital engineering data. In cases of emergency shutdowns, the needed document is always accessible to everyone online without having to meet face-to-face.

Today, there is additional reliance on workflows and workgroup features facilities through digital processes. Disruptions to the way teams are used to working, typically together in the same building, is even more evident now that engineers from a single department are working remotely.

Workflow and commenting features in an EDM system or BIM platform have become critical. Now, engineering teams need to gather feedback and review online information while ensuring that the most up-to-date versions are assessed, and digital workflows and online reviews are easy to follow.

Accessing reviews, comments and mark-ups are trackable within Meridian, while signoffs are electronic, helping to keep your operation in compliance. Employees can “see” the assets, without having to be in front of them. The option for remote collaboration, digital workflows and online reviews is key to ensuring plant uptime when traditional methods of working face-to-face are no longer an option.

Dealing with hundreds or thousands of paper copies is cumbersome and time-consuming. Rather than going into an archive to get information prior to performing building maintenance, people now can look it up digitally. Meridian makes all engineering documentation accessible to those who need it. It ensures version control, manages change audits and negates the need for digging through physical copies.

Supporting time-sensitive needs and not having to deal with firewalls for authentication, while having the ability to easily connect from anywhere via their mobile devices, makes it easier for our customers and their contractors to continue business as usual.

In order to come out strong when we can all finally get back to business, having the ability to forecast needs and prepare for the future will help dictate whether the return is a success or a failure. Time-saving measures put in place now can reap enormous benefits later. Knowing that employee anxiety is high and financial analysis can be harsh, implementing time-saving tools such as a proven EDM/BIM systems to help with safety, compliance and efficiency can be key to pushing through 2020 and succeeding in 2021.

There is always a level of uncertainty in future planning. However, one thing is certain, businesses that leverage digitization for their critical asset management and incorporate an EDM/BIM program will be ready for anything, while having a single source of truth for their most expensive capital assets.

Be prepared with Accruent’s Meridian solution. For further information, contact us today.

Cloud-based engineering document management systems are ideally suited to enable remote work and access for greater business continuity.

Discover four ways Meridian EDMS’s document version control functionality can increase collaboration while decreasing project turnaround time.

See how Seattle City Light Utilities implemented Meridian EDMS to attain document versioning control and data integrity over its 100 years’ worth of ...

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.