Document Version Control: Everything you Need to Know

Learn about document version control and how Accruent software helps your team reduce errors, stay compliant, and manage changes with full ...

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Self-Service & Support

Looking for self‑service training, best practices, helpful videos, product resources, or support? You’re in the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

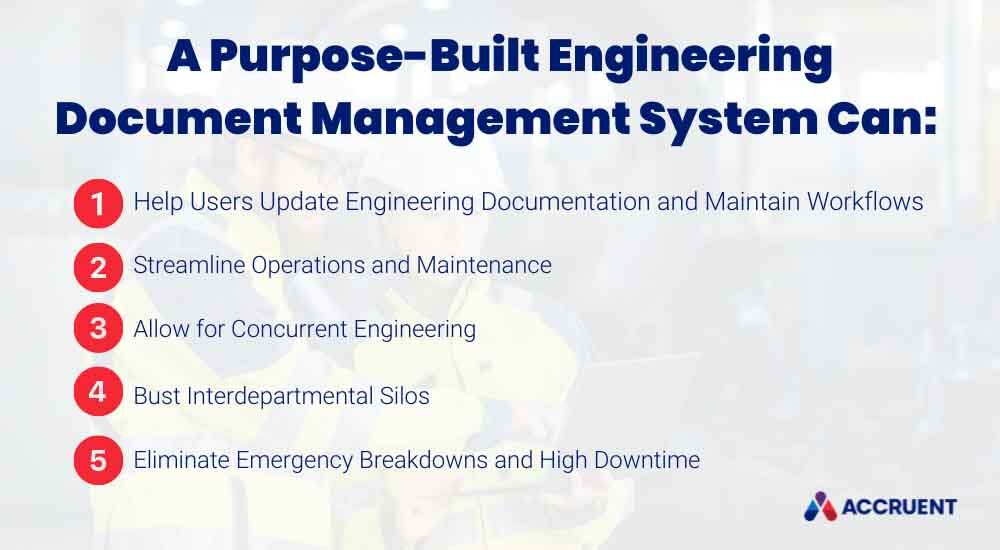

A purpose-built EDMS has the advanced functionality to support complex engineering information while streamlining operations and maintenance.

You would never give your maintenance team just a hammer for all the jobs they need to complete, right? Think about it: to do their job correctly, maintenance technicians need specific tools like a multi-meter, a torque wrench, or a simple Philips screwdriver. And if you only give them a hammer, you’re asking them to fail. Even if you have the most skilled team in the industry.

Well, if you only give them a work order without access to a connected, searchable document management system, you're only giving them a hammer. What’s worse, you’re leaving your team struggling to manually document, submit and initiate changes. And the results can be disastrous, leading to documentation errors, safety issues, skyrocketing work order costs, poor document version control and more.

> Watch Video: Meridian EDMS: Your Lifeline to Operations Safety

The worst part? This is exactly the situation that most organizations without a dedicated engineering document management system (EDMS) find themselves in (whether they know it or not). Here are the pitfalls to look out for and how a dedicated EDMS can help.

Out-of-the-box document management tools— and even enterprise content management systems (ECMs) — do have a place in industry, as these generic tools can help organizations share and save static documentation such as legal and financial documents, marketing collateral and scanned posts. Even at Accruent, we utilize tools like SharePoint to store and access blogs, social media content and sales decks. For such instances, these tools can facilitate sharing across departments, allow for cloud-based collaboration and more.

That said, these standard tools simply don’t have the advanced functionality required to support the complex business processes and the unique file formats critical to engineering departments and capital project teams. Again, these general ECM tools work best on static, linear documents: documents that are created, edited and stored in a linear fashion. A blog, for example, is written, edited, published then left largely unchanged.

Most technical documentation – like facility documentation, technical manuals, CAD drawings and engineering documents – are neither static nor linear. Instead, this documentation must be regularly updated, approved, redlined, version tracked and controlled. That’s the only way it can reflect the as-built environment and effectively manage change throughout the life of an asset. What’s more, this documentation is generally:

This makes engineering documentation very difficult to manage, access and utilize— even when there is another robust system, like a CMMS, in play. Getting this right is nearly impossible on a free or company-wide ECM system.

A dedicated purpose-built system, on the other hand, can alleviate many of these concerns.

By streamlining engineering document management, increasing transparency and helping users effectively manage change, a purpose-built engineering document management system can ultimately help organizations ensure compliance, control engineering project costs, improve safety, extend asset life and protect brand reputation.

Here’s how.

As we mentioned, ECMs are not built for dynamic engineering content. Expanding on this issue, these systems don’t support CAD drawing files, they don’t have a CAD authoring integration and they don’t support Building Information Management (BIM) systems. Trying to make them work for this kind of information will likely require:

And it will still be hard to update your documentation, maintain workflows, collaborate and ensure that your information reflects the built environment. A dedicated EDMS, on the other hand, is purpose-built to allow users to store, maintain and update CAD documentation and BIM models. Specifically, your team can use a dedicated EDMS to:

The right tool won’t just help with design and construction – it will also streamline the handover process and help operations and maintenance during an asset’s operational lifecycle. By allowing users to have centralized access to critical asset and facility data, a dedicated EDMS can provide key data and documentation needed to streamline:

Engineering content is often under change in more than one project at a time, leading to the need for “concurrent engineering.” For example, a multi-year plant expansion may require the modification of hundreds of documents and drawings, but other, short-term projects need to modify a subset of documents and drawings to reflect as-built changes to the operational environment. Generic content management tools cannot manage these workflow overlaps or interrelations.

Without concurrent engineering, the alternatives are to risk not reflecting project information back into as-built content or to serially stage projects, leading to benefit delays. With a purpose-built tool like Meridian, on the other hand:

Unfortunately, the information used by engineering and maintenance teams is usually siloed, as these teams often use separate systems and (often manual) processes. This can lead to many problems, including:

These, in turn, can snowball into broader efficiency and communication issues. It can also make it hard to ensure that your operations and maintenance departments are working with up-to-date technical asset information.

By storing all asset-related data, providing workflow controls and integrating with critical maintenance tools like a CMMS, the right EDMS can resolve these concerns and provide a centralized, up-to-date single source of truth. This can not only eliminate confusion and rework but also maximize safety, efficiency and interdepartmental collaboration.

Downtime is a killer for any organization. Though it’s hard to quantify the exact number, estimates show that downtime can cost factories anywhere from 5%-20% of their productivity, and high downtime can negatively impact budget, processes, production...the list goes on.

Having centralized systems powered by comprehensive documentation and analytics can help lower downtime by allowing your team to:

Manual processes can be killers of productivity and accuracy, especially for large organizations with many document sources, departments, assets and concurrent engineering processes. The right tool will provide business-critical automations, including:

Engineering teams that opt for free or out-of-the-box document management tools are making huge sacrifices when it comes to efficiency, change management, workflow processes and document version control (and that’s just scratching the surface).

This can cost money, negatively impact efficiency, compromise safety and even lead to staffing issues and a major skills gap as tenured employees retire—taking their tribal knowledge with them – and new hires look elsewhere for jobs that offer more efficient and modern technologies. Don’t let this happen to your organization. Implement a purpose-built EDMS.

Learn about document version control and how Accruent software helps your team reduce errors, stay compliant, and manage changes with full ...

Explore why “free” document management tools are actually costing your company time and money, and how to solve for it by switching to Meridian EDMS.

Discover four ways Meridian EDMS’s document version control functionality can increase collaboration while decreasing project turnaround time.

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.