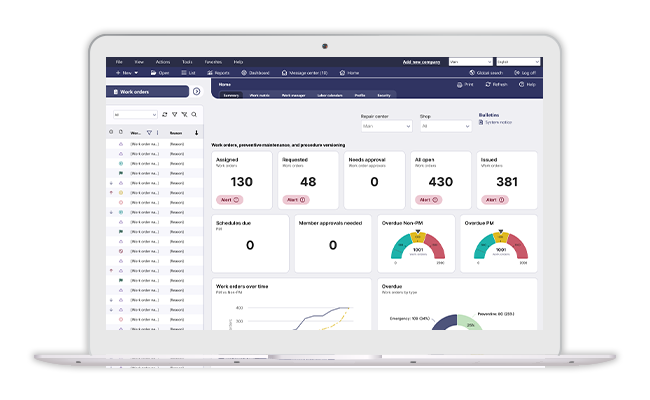

Accruent and Maiprosoft Team Up to Accelerate Digital Transformation Across the Middle East and Asia Pacific

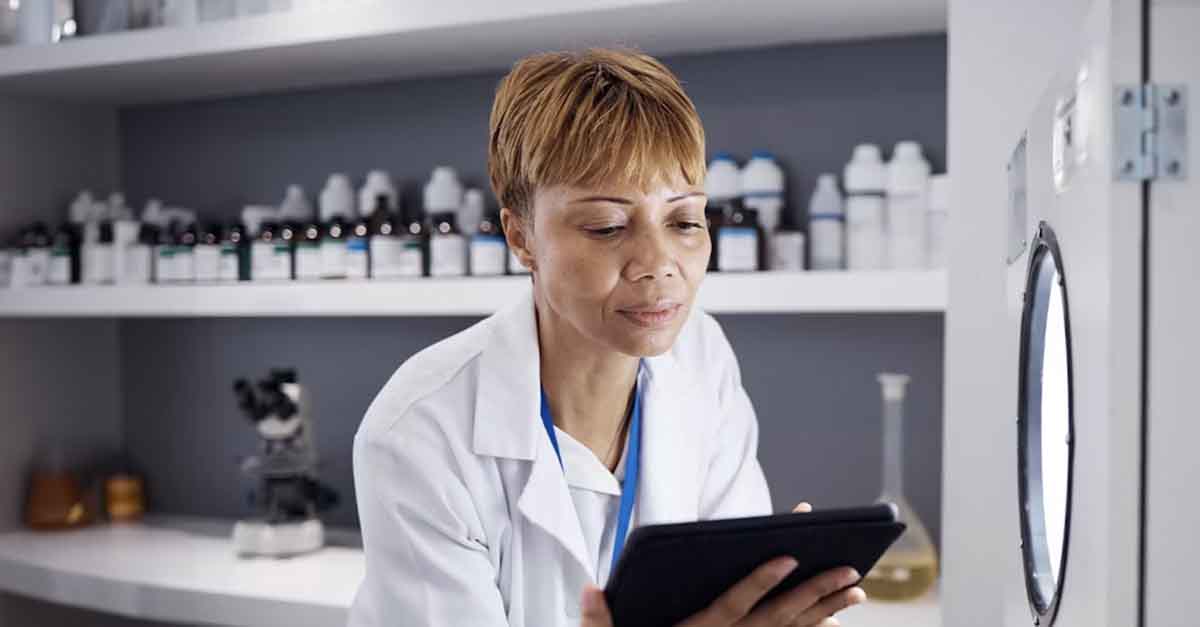

Accruent partners with Maiprosoft to accelerate digital transformation in the Middle East and Asia Pacific, addressing regional tech deployment and compliance challenges.