Best Building Maintenance Management Software of 2025

Accruent's facility maintenance software keeps your business running by streamlining work order management and prioritizing preventative maintenance.

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

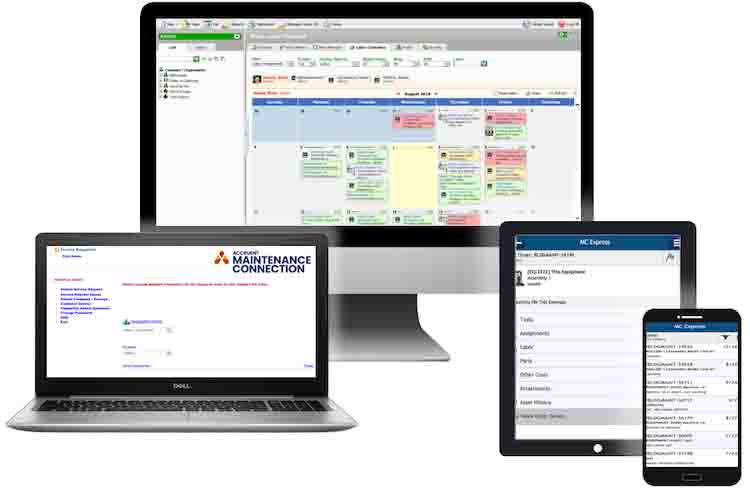

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Self-Service & Support

Looking for self‑service training, best practices, helpful videos, product resources, or support? You’re in the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

Explore tried-and-true best practices that will help you get the most out of your retail facilities management software

Table of contents

There are 10 proven best practices to enhance your systems for better facilities management, facility maintenance, and equipment maintenance management:

Good facility management allows a facilities maintenance manager easy access to asset-level data. You can establish operational benchmarks, foresee and prevent breakdowns or failures, assess production costs accurately, focus on warranty issues and claims, lower operating costs, and manage service provision confidently.

As you gather granular data from each asset, you can review and confirm your total facilities maintenance budget to reduce overruns and eliminate surprises.

When you gather data centrally, call-center automation can streamline the process of facilities maintenance and ensure that you do not waste time dispatching service technicians.

Call center and facility maintenance managers should be able to oversee the entire maintenance activity operation using dashboards to ensure that call center teams are dispatching a work order and the right facility maintenance worker both promptly and appropriately.

Maintenance service providers will need to deal with anticipated events or unexpected failures. You want to conduct this process quickly and efficiently to hold down operating costs such as the costs associated with food spoilage, lost revenue, and customer dissatisfaction to ensure that you stay within your facility maintenance operations budget.

Learn how to predict potential failures of equipment remotely using performance data.

You can use aggregated data to establish attributes for each site or location. Some examples include gross square footage, heated or air-conditioned square footage, ceiling height, roof type, roof color, building orientation, window films used, window area, and lighting types. Then, you can monitor these attributes to provide executive-level data for strategic purposes, footprint information, and other portfolios.

Your systems should be able to track weather data and other external events as well as integrate data related to external events into your reports and analytics. When carefully gathering and analyzing operating data, such events may no longer cause operational difficulties or strain your facility maintenance budget.

Get the performance characteristics of each asset, such as manufacturer ratings for wattage, amperage, revolutions per minute (RPM), as well as actual energy consumption, repair history, and many other metrics. Understand the asset performance in detail at the asset level (not at the category level). With more granular data, you can conduct better correlation and analysis and troubleshoot problems more efficiently.

Maintain detailed warranty data for each significant asset in each location so that the system can trigger appropriate actions automatically.

Systems should allow external service providers to access the asset management system at the appropriate level through kiosks on-site. Service providers and local store associates can use the kiosk to configure and modify a work order for a maintenance technician, report work completed, and close work orders efficiently.

Download our free Facility Management Checklist to streamline maintenance, improve space utilization, and stay on top of compliance.

Accruent's facility maintenance software keeps your business running by streamlining work order management and prioritizing preventative maintenance.

Discover why a solution comprising remote monitoring, mobile workforce management, and asset and facilities management gives you maintenance ...

IoT will continue to have a massive impact in the maintenance management field - and it's a technology that you shouldn't sleep on.

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.